导航 Classified

CHINA permanent magnet synchronous motor industry: high-performance magnetic materials push up costs

Permanent magnet motors generate electric power through the interaction between the stator coil and the permanent magnetic material on the rotor. They are composed of core components such as the rotor, stator, housing, and bearings. Compared with traditional motors, they do not require excitation coils and external energy, and have the advantages of simple structure, reliable operation, light weight, and high efficiency. They are currently widely used in industrial automation, automobiles, household appliances, and other fields.

Because permanent magnet synchronous motors do not require brushes and excitation current, they have higher efficiency and power density than traditional motors. In terms of overload capacity, except for DC motors, the other varieties are not much different. The efficiency and power factor of permanent magnet synchronous motors are the most outstanding performances. The efficiency can reach 85-97%. Although small motors can usually reach more than 80%, compared with the 40-60% efficiency of asynchronous motors, permanent magnet synchronous motors have obvious advantages. In terms of power factor, it can reach more than 0.95, indicating that the proportion of active current component of permanent magnet synchronous motors to total current is greater than that of other types, and the utilization rate of electric energy is higher.

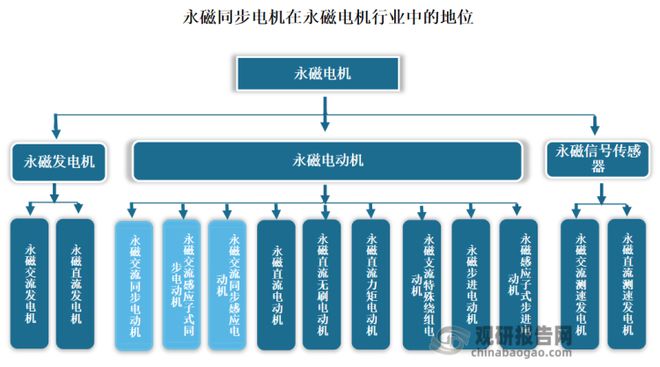

Permanent magnet synchronous motors are a type of permanent magnet motor, and their market development is affected by the permanent magnet motor market. Permanent magnet motor is the product of the combination of modern materials science, electronic power science and motor control theory. In recent years, with the continuous improvement of the performance of permanent magnet materials and the development of motor technology, permanent magnet motors have been widely used in various fields of the national economy, making the market continue to develop. Relevant data show that the market size of permanent magnet motors in my country is estimated to be around 11.46 billion yuan in 2022.

At present, my country has become the global production base of permanent magnet motors, and some domestic products are exported to overseas markets. Relevant data show that the output of permanent magnet motors in my country reached 4.149 billion units in 2021. It is estimated that the output of permanent magnet motors in China will be around 4.328 billion units in 2022.

From the upstream point of view, the main raw materials required for the production of permanent magnet synchronous motors include magnetic materials (for example: neodymium iron boron magnets, permanent magnet ferrites, samarium cobalt, aluminum nickel cobalt), copper, steel, insulation materials, aluminum, etc., among which high-performance magnetic materials are the key to manufacturing efficient permanent magnet synchronous motors. The downstream of the permanent magnet synchronous motor industry is mainly terminal applications, such as wind power, new energy vehicles, aerospace, mechanical equipment, CNC machine tools and other fields. In the future, with the continuous upgrading of downstream manufacturing industries, the increase in demand in the terminal application market is expected to drive the further expansion of permanent magnet synchronous motors.

The raw materials of permanent magnet synchronous motors mainly include magnetic materials (such as neodymium iron boron magnets, permanent magnet ferrites, samarium cobalt, aluminum nickel cobalt), silicon steel sheets, copper, steel, aluminum, etc. Among them, magnetic materials, silicon steel sheets and copper are the main components of raw material costs, accounting for more than 50%. Although, according to the cost structure of traditional motors, the initial purchase, installation and maintenance costs of motors only account for about 2.70% of the entire life cycle of the motor, considering the pricing, competitiveness and popularity of the products, motor manufacturers still pay more attention to raw materials.

(1) Magnetic materials

Magnetic materials are the key to the high efficiency of motors, accounting for more than 25%. Magnetic materials are super strong magnetic substances, which are ancient and widely used functional materials. Modern magnetic materials are used in our lives, such as permanent magnet materials used as motors, core materials used in transformers, magneto-optical disks used as storage, and magnetic recording floppy disks for computers. Magnetic materials can be divided into soft magnetic materials and hard magnetic materials according to the difficulty of demagnetization after magnetization.

In recent years, with the construction and development of my country's new infrastructure, the development of new generation information technology and digital economy, rail transit, energy conservation and environmental protection, and new energy and other application fields, a broad market space has been provided for the development of my country's magnetic materials industry. With its abundant resources and labor advantages, as well as huge supporting market support, my country is gradually becoming the world's largest production base and sales market for magnetic materials. Data show that my country's magnetic material output in 2022 will be 1.821 million tons, a year-on-year increase of 7%; demand will be 2.007 million tons, a year-on-year increase of 6.8%.

At present, rare earth magnets are commonly used magnetic materials with strong magnetic properties and are suitable for high-performance and high-power applications. Among them, neodymium iron boron and cobalt magnets are important applications of rare earth materials in the field of permanent magnetic materials. Because my country has abundant rare earth reserves, the output of neodymium iron boron accounts for about 90% of the global proportion. However, it is worth noting that due to the particularity of rare resources, the production and processing process of neodymium iron boron is relatively complicated, so the price of permanent magnet motors is higher than that of traditional motors. The proportion of magnetic materials in the total cost is usually 30%. (2) Copper materials

Copper materials refer to pure copper or copper alloys made into various shapes, including rods, wires, plates, strips, bars, tubes, foils, etc. Copper materials are processed by rolling, extrusion and drawing. Copper plates and bars are hot-rolled and cold-rolled; strips and foils are cold-rolled; tubes and bars are divided into extruded products and drawn products; wires are all drawn. Copper materials include copper plates, copper rods, copper tubes, copper strips, copper wires, copper bars, copper foils, etc.

In recent years, with the advancement of "carbon peak and carbon neutrality", urbanization and consumption upgrades, the copper consumption field has continued to expand and the consumption intensity has continued to increase. The new infrastructure field and the charging pile market continue to develop, the State Grid's investment has continued to increase, and the expenditure on UHV and distribution network projects has increased, which is beneficial to the downstream copper demand; my country vigorously promotes the development of new energy industries such as new energy vehicles and photovoltaics, which is beneficial to the development of copper products such as electromagnetic wires for new energy industries; the growth of applications in electronic fields such as 5G mobile phones will drive the rapid growth of copper demand. Data shows that my country's copper demand in 2022 is 22.621 million tons, an increase of 1.487 million tons from 2021.

In terms of production, due to increasingly fierce competition in the copper industry in China from 2017 to 2018, the high degree of homogeneity led to overcapacity, which to a certain extent affected the domestic copper production, resulting in a decline in my country's copper production during this period. However, in recent years, with the continuous expansion and development of new energy and electricity and other fields, the overall demand for copper has increased significantly, driving the growth of production. Data shows that my country's copper production increased to 22.865 million tons in 2022, an increase of 1.63 million tons from 2021. From January to November 2023, my country's copper production was 20.211 million tons, a year-on-year increase of 4.6%. After a long period of development, my country has now become the world's largest copper producer, trader and consumer. The production and consumption of copper accounts for more than 60% of the world's total, and it occupies an important industrial position in the international copper processing industry. 3) Silicon steel sheet

Silicon steel sheet, also known as electrical steel, is an important soft magnetic alloy indispensable for the power, electronics and military industries. It is also the largest metal functional material, mainly used as the iron core of various motors, generators and transformers. Silicon steel sheets are complex and have strict manufacturing technology. Foreign ones are protected in the form of patents and regarded as the life of the enterprise.

In recent years, with the upgrading and transformation of my country's power system and the rapid development of new energy, the demand for electrical steel has continued to increase. According to market survey data, the current domestic electrical steel market size has exceeded hundreds of billions of yuan. At the same time, with the rapid development of new energy vehicles, smart grids and other fields, the application scope of electrical steel will be further expanded. In addition, with the continuous innovation of technology, the performance of electrical steel will continue to improve to meet more stringent use requirements. Therefore, in the long run, my country's electrical steel market has broad development prospects.

Against the above background, related enterprises are constantly expanding, and the market capacity and output are growing. According to relevant data, during the "13th Five-Year Plan" period, my country's electrical steel capacity and output exceeded 10 million tons for several consecutive years, becoming a major producer and consumer of electrical steel in the world. As of 2021, my country's electrical steel production capacity reached 14.48 million tons, an increase of 1.72 million tons compared with 2020; the output reached 13.1828 million tons, an increase of 17.9% year-on-year.

Downstream market situation

(1) Wind power

Permanent magnet motors play an important role in the field of wind power generation. Based on the excellent performance advantages of permanent magnet motors, they have become the preferred motor for wind power generation systems. In the downstream field of permanent magnet motors, wind power generation accounts for more than 20%, ranking first. From a long-term trend, with the continuous growth of global demand for clean energy, it is expected that future applications will continue to expand.

Wind power generation Wind power generation refers to the conversion of wind kinetic energy into electrical energy. It is a clean energy technology. The principle of wind power generation is to use wind power to drive the wind turbine blades to rotate, and then increase the speed through the speed increase device to drive the generator to generate electricity, converting wind energy into mechanical energy, and then converting it into electricity.

In recent years, under the background of carbon peak and carbon neutrality, my country's wind power industry has ushered in a period of rapid development, with installed capacity and power generation growing continuously. So far, my country has become the country with the largest installed capacity of wind power in the world. In the future, benefiting from the global consensus on carbon peak and carbon neutrality, China's and the world's wind power installed capacity will continue to increase, and the new demand for wind power equipment coating and maintenance will maintain a good development trend. Data show that my country's wind power installed capacity will be about 440 million kilowatts in 2023, a year-on-year increase of 20.7%; of which the new installed capacity will be 75.9 million kilowatts, a year-on-year increase of 105%, a record high. 2024 is a key year for achieving the goals and tasks of the "14th Five-Year Plan". It is estimated that the annual new wind power installed capacity will be around 75 million to 85 million kilowatts, and the domestic wind power market has great potential.

(2) New energy vehicles

The motor is one of the three core components of new energy vehicles and is known as the "heart" of new energy vehicles. However, due to the space limitations and operating environment requirements of electric vehicles, traditional power electronics and motor technologies have been unable to meet their high performance, small size and strict ambient temperature requirements. Therefore, permanent magnet motors, as one of the key technologies of electric vehicle motor drive systems, have received widespread attention. At present, the common motors on the market are permanent magnet synchronous motors and AC asynchronous motors, each with its own advantages and disadvantages. The industry generally believes that from the perspective of comprehensive performance, permanent magnet synchronous motors have the most advantages. Relevant data show that in 2021, the installed capacity of permanent magnet synchronous motors in domestic new energy vehicles has exceeded 98%, and it has become the most widely used drive motor in China's new energy vehicles. In addition, the new energy vehicle field currently accounts for 15% of the downstream application proportion of permanent magnet motors, ranking second. It can be seen that with the continuous expansion of the new energy vehicle market, the permanent magnet synchronous motor industry will usher in more opportunities.

In recent years, the government has introduced a number of policies to support the development of new energy vehicles, including domestic pure electric vehicles and plug-in hybrid vehicles. For example, in the "New Energy Vehicle Industry Development Plan (2021-2035)", it is clearly stated that in 2025, the sales volume of new energy vehicles in my country will reach about 20% of the total sales volume of new vehicles. The introduction of the plan has greatly encouraged the upstream and downstream of the new energy industry of independent brand automobiles, and the industry has shown explosive growth momentum. According to statistics from the China Association of Automobile Manufacturers, in 2022, my country's production and sales of new energy vehicles will reach 7.058 million and 6.887 million respectively, up 96.9% and 93.4% year-on-year respectively. Among them, the production and sales of new energy passenger vehicles will reach 6.716 million and 6.549 million respectively, up 97.77% and 94.26% year-on-year respectively; the production and sales of new energy commercial vehicles will reach 342,000 and 338,000 respectively, up 81.84% and 78.89% year-on-year respectively.

In 2023, the production and sales scale of new energy vehicles in my country reached a record high. Data shows that in 2023, the production and sales of new energy vehicles in my country will reach 9.587 million and 9.495 million respectively, up 35.8% and 37.9% year-on-year respectively, accounting for more than 60% of the global share and ranking first in the world for 9 consecutive years; the export of new energy vehicles will reach 1.203 million, up 77.2% year-on-year, both of which are record highs.